Our Top Recommendation to Reduce Crop Loss

How to Reduce Crop Loss?

Crop loss is common on all farms, but there are some tried and true ways to reduce crop loss on your farm.

- Select disease-resistant crop varieties

- Test soil and fertilize accordingly

- Manage irrigation properly

- Control weeds

- Proper Combine Maintenance

- Harvest at the right time

- Handle crops carefully

- Store crops properly

- Package crops for protection

While corn yields have steadily increased in the US since the late 1930s, crop loss can still be costly to the farmer. At CNH Reman, we can't guide you in crop varieties or proper storage, but we are experts in enhancing combine efficiency and performance, which is essential to a profitable yield. During harvest, header losses occurring during gathering can result in significant crop loss. The grain left behind by the combine head and cleaning process, where the grains are blown out of the combine along with crop residue, are referred to as threshing losses.

According to a 2021 study from the University of Georgia, farmers lose approximately 1 bushel of corn per acre during harvest. The loss was measured by counting the corn kernels lying in the residue of a 2.5x-foot rectangle, which was calculated to be two kernels per square foot, resulting in a loss of up to 1 bushel.

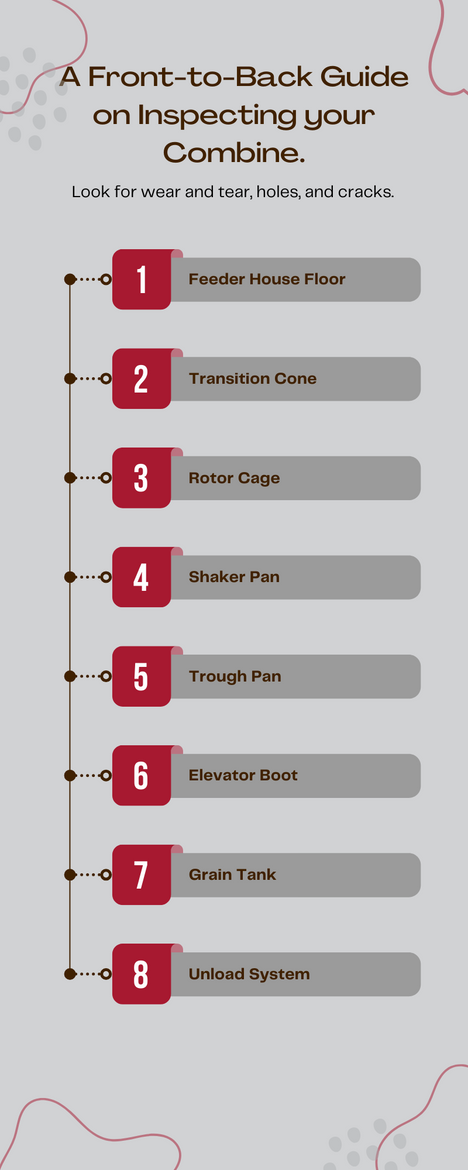

What should you inspect on your combine?

To combat grain loss in your combine, you should thoroughly inspect your combine from front to back, starting with your feeder house floor and continuing to the transition cone. Things to look for in any of the areas where grain initially passes through include: wear and tear, holes, and cracks. From there, inspect your rotor cage for any wear, then move onto the shaker pan, which should be free of visible holes and cracks. Next, inspect your trough pan and elevator boots for wear, followed by your grain tank. The final inspection should be your unload system, making sure to note any holes found along the extension tube. If you have noticed wear or holes in any of these areas, one easy solution is to line those high-abrasion areas with a CNH Reman Wear Part by Ihle Fabrications. Installing liner kits anywhere the grain touches can help preserve the quality of the combine and protect it from further crop loss. All CNH Reman Wear Parts are made with dent and abrasion-resistant materials such as Hardox® 450, a high-grade steel that is stronger than the OEM. The benefits of replacement liners are:

- Ease of installation

- Lower cost of the liner vs. replacing the entire component

- Improved combined performance with reinforcement in areas that wear

- The prevention of crop yield loss

For example, lining your auger tube with a CNH Reman Bubble Up Liner is as simple as removing your auger, sliding our Bubble Up Liner into place, and installing the eight bolts to hold it in place. As a bonus, this will cost you a fraction of what you would pay to replace the entire auger tube. By lining the high-grain traffic areas with an extra layer of protection with a CNH Reman liner, you can ensure your combine will run to maximum efficiency with minimal grain loss due to wear and tear and holes in your threshing areas.

To learn more about our parts, visit www.mycnhreman.com/wearparts. CNH Reman Wear Parts by Ihle Fabrications are available through your local Case IH and New Holland dealerships.